Not known Factual Statements About Casters Manufacturer

Wiki Article

The Ultimate Guide To Casters Manufacturer

Table of ContentsThe Casters Manufacturer PDFsAn Unbiased View of Casters ManufacturerThe 6-Second Trick For Casters ManufacturerExcitement About Casters ManufacturerThe Ultimate Guide To Casters ManufacturerSome Ideas on Casters Manufacturer You Should Know

While most artificial wheels are perfect for high-impact and also severe scenarios, they are louder than softer products and also are less flexible when ramming debris. Phenolic wheels, which are made of phenolic resin as well as macerated canvas, are a constant option for push pull applications. Phenolic wheels are strong as well as withstand oil as well as other chemicals, making wheelchair much easier.Gray iron is utilized to make actors iron wheels. They're abrasion-resistant as well as start rolling with little effort. These wheels are very lasting, made for high-capacity applications, and can tolerate remarkable heat. This kind of caster wheel can operate concrete and smooth steel surface areas. Some of the specifications found on this caster wheel consist of hardness of 90-95A; Brinell 145.

This kind of caster wheel can run in the list below problems: moderate chemicals, oily and greasy locations, steel chips externally, high warmth (+250 F), as well as extreme cold (+45 F). To decrease leading and rolling effort, the flanged wheel is created to work on steel tracking. Rolling on tracks has the included advantage of reducing the toll of load capacities on floors, permitting bigger ability, less complex rolling, and flooring protection.

Not known Facts About Casters Manufacturer

The solid wheels are unbreakable in normal use, can endure high temperatures, and take in shock and influence without failing. Forged steel wheels outshine ductile steel wheels in regards to lots ability, impact toughness, as well as rollability of all wheel wheels. Forged steel caster wheels can be run on concrete as well as smooth steel surfaces.

Bearings that can be used include plain, tapered, Teflon, and roller bearings. These caster wheels can operate under the exact same problems which are moderate chemicals, oily and also oily areas, and metal chips externally. These wheels are made up of a nylon and glass mix as well as are crafted to stand up to severe temperature levels.

Fascination About Casters Manufacturer

Glass filled nylon wheel wheels have a solidity of 65D. These wheel wheels utilize either plain, roller, or spanner bearings.Hard rubber wheels have a larger lots ability than soft rubber wheels and also will certainly not squash while resting under loads, unlike soft rubber wheels. Many chemicals, oils, oil, solvents, as well as cleansing representatives are resistant to difficult rubber wheels.

Rumored Buzz on Casters Manufacturer

Tough rubber wheel wheels bring about sound decrease and also flooring security. Pneumatically-driven caster wheels are well matched for aerospace and also other applications.They safeguard the flooring, are non-marking and non-conductive, and also withstand abrasion far better than difficult rubber wheels. These wheels are immune to water, oils, oil, solvents, as well as numerous chemicals, making it perfect for application in bakeries, milk, food processors, meat processing, laundries, grocery stores, storehouses, as well as production. The additional thick, flawlessly molded gray rubber step is chemically bound to a light weight aluminum core for amazing robustness and movement on these wheels.

The Basic Principles Of Casters Manufacturer

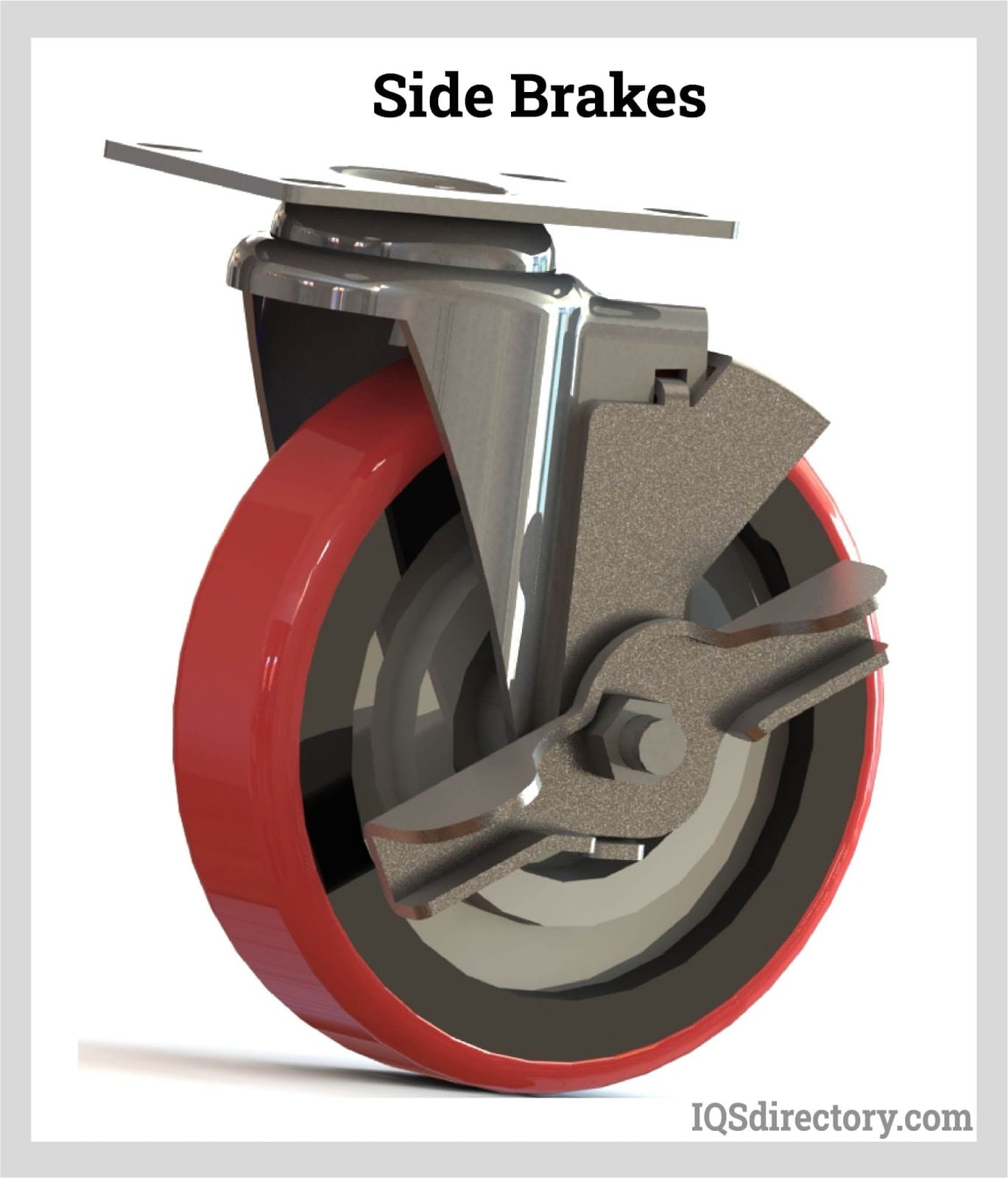

The "V" groove's layout ensures optimal weight distribution per wheel. For heavy-duty commercial wheels with brakes, brakes are a preferred option. Brakes permit individuals to stop and also keep carts in location, which can be helpful in some circumstances or improve safety and security by minimizing the risk of a runaway cart. There are various ranges of caster brakes readily available, each with its own set of features.A polyurethane cam is made use of in the polyurethane web cam wheel brakes. The web cam is then utilized to lock the wheel in position by tightening up a plate against the wheel's running surface area. A number of devices, including handles and also levers formed straight right into the webcam, can be made use of to operate the web cam.

An additional advantage of this kind of brake is that the actuation technique can be finished with the feet, which eliminates driver strain from flexing down to actuate with a hand - Casters Manufacturer. These brakes can be mounted on a caster's leading or tracking edge. Face get in touch with brakes work by pressing a plate onto the wheel's running surface making use of a threaded rod.

Casters Manufacturer Can Be Fun For Everyone

These brakes supply a solid holding pressure and are ideal for durable applications. These brakes can be set up on a wheel's leading or tracking side. The drawback of this type of brake is that find it requires the operator to flex over and also tighten or loosen the brake by hand, which puts much more strain on the driver as well as takes longer than a foot find more info actuated brake.Report this wiki page